Add to Cart

Type 441 Stainless Steel is a ferritic stainless steel which provides good high-temperature strength (exceeding that of Types 409 and 439 Stainless Steels) plus good corrosion resistance in many exhaust gas environments (equivalent to Type 439 and 18 Cr-Cb Stainless Steels). . Ferritic steels are not inherently strong at elevated temperatures, but columbium additions coupled with appropriate solution annealing markedly improve long-time creep rupture strength. Type 441 is dual stabilized with niobium and titanium to provide good weld ductility and resistance to intergranular corrosion in the weld heat affected zone.

Sheet, Strip

ASTM A240 (S43940) and EN 10088-2 (1.4509)

Automotive exhaust tube and components

| Element | UNS 43940 | EN 1.4509 |

|---|---|---|

| Carbon | 0.030 max. | 0.030 max. |

| Manganese | 1.00 max. | 1.00 max. |

| Sulfur | 0.015 max. | 0.015 max. |

| Phosphorus | 0.040 max | 0.040 max. |

| Silicon | 1.00 max. | 1.00 max. |

| Chromium | 17.5 – 18.5 | 17.5 – 18.5 |

| Titanium | 0.10 – 0.60 | 0.10 – 0.60 |

| Nitrogen | - | 0.045 max. |

| Niobium | 0.30+(9xC) min. | 0.30+(9xC) min.– 1.00 max. |

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2" Gauge length) | Hardness Rockwell |

|---|---|---|---|---|

| UNS S43940 | 36 min. | 62 min. | 18 min. | HRB 88 max. |

| EN 1.4509 | 36 min. | 62 - 91 | 18 min. |

439 stainless steel is a titanium stabilized ferritic stainless steel grade with , 18 percent chromium alloy, it designed to resist corrosion in a variety of oxidizing environments from fresh water to boiling acids, its corrosion resistance similar to that of 304/304L stainless steel. Type 439 may also be used in many oxidizing environments where Type 304 is considered adequate in terms of general corrosion resistance but is subject to chloride stress corrosion cracking. This variation does not require annealing after welding to restore ductility or to provide intergranular corrosion resistance. Type 439 also has superior formability capabilities and is heavily used in the automotive industry; it can be work hardened slightly to increase tensile strength.

Excellent resistance to stress corrosion cracking, good weldability, high thermal conductivity and low thermal expansion characteristics make Type 439 stainless steel an ideal consideration for many applications, typical applications include tubular manifolds and exhaust system components.

Stainless steel grade 439 has good weldability, brightness, and pitting corrosion resistance. It polishes well, and is good for deep drawing.

| Grade | C | Si | Mn | P | S | Cr | Ni | N | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 439 | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 17.00 – 19.00 | 0.5 | 0.030 | [0.20+4(C+N)] Min, 1.10 Max; | Bal |

| TP439 | 0.07 | 1.00 | 1.00 | 0.040 | 0.030 | 17.00 – 19.00 | 0.5 | 0.040 | [0.20+4(C+N)] Min, 1.10 Max; | Bal |

Max, %, 439 for ASTM A240 Plate, Sheet and Strip, TP439 for ASTM A268 seamless and welded tube

| Grade | Tensile Strength (MPa) Min | Yield Strength 0.2% Proof (MPa) Min | Elongation (% In 50mm) Min | Hardness Rockwell B (HR B) Max | Hardness Brinell (HB) Max |

|---|---|---|---|---|---|

| 439 | 415 | 205 | 22 | 89 | 183 |

| TP439 | 415 | 205 | 20 | 90 | 190 |

439 for ASTM A240 Plate, Sheet and Strip, TP439 for ASTM A268 seamless and welded tube

| Physical Property | Value |

|---|---|

| Density | 7.70 G/Cm³ |

| Melting Point | 1505 °C |

| Thermal Expansion | 11.0 X10^-6 /K |

| Modulus Of Elasticity | 220 GPa |

| Thermal Conductivity | 25.0 W/M.K |

| Electrical Resistivity | 0.60 X10^-6 Ω .M |

| USA UNS | EU EN | Japan JIS | Germany DIN | Russia GOST |

|---|---|---|---|---|

| 439 S43035 | X3CrTi17 | SUS430LX | 1.4510 | 08KH17T |

439 stainless steel is resistant to attack by potable water and many mildly or moderately corrosive chemical environments which are oxidizing in nature. In various chloride solutions, studies have shown pitting resistance of Type 439 to be superior to that of Type 304. In addition, Type 439 is not subject to stress corrosion cracking which may cause premature failure of austenitic steels in chloride bearing environments such as hot waters used in heat exchangers.

439 stainless steel is weldable by the usual stainless steel methods including spot welding, TIG, MIG, laser and high frequency tube welding. Conventional gas shielding is used with the tungsten or metal arc process. If filler wire is added to the weld deposit, a stabilized stainless steel or a nickel base alloy should be considered in order to maintain corrosion resistance in the weld metal. For elevated temperature applications such as automotive exhaust systems, type439 and type 444 alloys would be preferred to maintain thermal expansion compatibility. Properly welded, grade 439 alloy retains the corrosion resistance and almost all of the mechanical properties of the base metal in the weld fusion and heat affected zones. Due to the titanium content, the weld metal will be free of the martensite normally associated with the ferritic stainless welds. Further, due to this titanium content, the heat affected zone is resistant to intergranular corrosive attack in environments in which the base metal is satisfactorily used. Welding this alloy even with adequate gas protection may cause some heat tint or oxidation that should be removed to insure maximum corrosion resistance.

Stainless steel 439 alloy should be annealed between 1450 and 1600°F (790 and 871°C) and quickly cooled. Cooling rates affect impact transition with slow cooling producing higher, less desirable impact transition. Ferritic stainless steels containing more than about 12% chromium have a susceptibility to a phenomenon known as 885°F (475°C) embrittlement. This embrittlement is observed as a degradation of impact properties at room temperature resulting from very long exposures in the temperature range of 700 to 1000°F (371 to 537°C). If service temperatures are cycling through this range, exposure above about 1050°F (565°C) restores the room temperature toughness properties. When there have been long dwell times near 885°F (475°C), service temperatures that cycle above about 1050°F (565°C) are beneficial rather than detrimental.

The unique blend of properties of 439 stainless steel make it a desirable choice for many applications. It has been used with 25 years of documented service in hot water tank applications requiring good overall corrosion resistance, resistance to stress corrosion cracking and good weldability. The alloy’s oxidation resistance permits its use in residential furnaces and automotive exhaust system components. 439 alloy corrosion resistance, fabricability and reflective color compatibility have resulted in its use as small diameter tube to replace solid wire spokes in automotive wheelcover applications. The alloy has replaced carbon steel heat exchanger tubes without expansion joints because of its low coefficient of thermal expansion. 439 alloy higher thermal conductivity, compared to conventional stainless steel, has resulted in its choice over Type 304 in a number of feedwater heater applications. The successful application of any alloy is dependent upon many variables. It is important to consider these carefully before selecting any material, including 439 stainless steel.

Stainless steel grade 439 is capable of being made into complex shapes such as tubular manifolds and exhaust system components, where temperatures tend to go beyond the oxidation limit of grade 409 steel. 439 stainless steel is preferred where wet corrosion resistance especially to chlorides is needed.

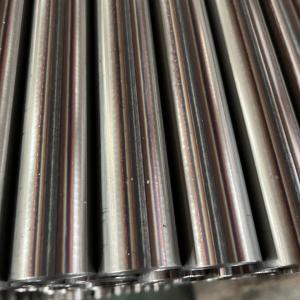

Product picture:

Packing&shipping: